Typeset page arranged (mirror image) for the press.

Early Linotype machine. This device (a rather elaborate contraption to today's engineering eye) actually assembles a mold, character by character, for a column-width line of type. Once completed, this is carried into the foundry portion of the machine where it is filled with molten metal of a composition similar to common solder, which very quickly cools to form a slug of type. Stacked in a frame, line-by-line, these then are mounted in the printing press where ink is applied and transferred to paper to effect printing.

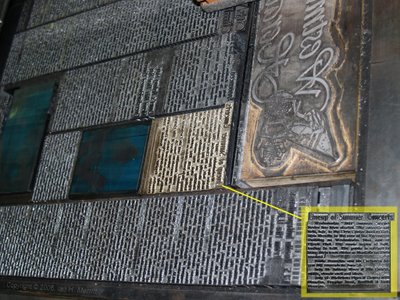

Close-up of the plaque featured in the shot above.

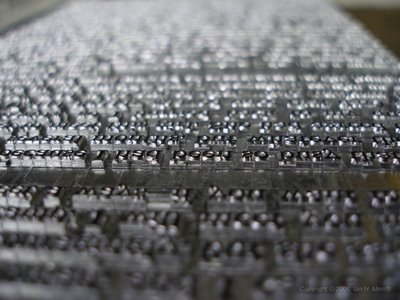

The assembly carriage in the Linotype machine in which individual letter molds, each referred to as a mat, short for matrix, are stacked to form the mold into which the molten metal is injected. A fascinating aspect of this machine, and a significant part of its complexity, is what happens to all the little matrix parts after the slug is cast. A long arm drops down, grabs and lifts them to a small conveyor track above the magazine that queues these for assembly. There, they are driven across a very clever sorting mechanism. Every matrix for a particular character has cut into it a set of teeth resembling those of a key. The sorting mechanism identifies the appropriate slot into which to drop each matrix by the particular set of teeth it has. These slots directly feed into the magazine making the character available for re-use.

Close-up of a mat or matrix from the sorting end. A unique pattern of teeth mechanically identifies each character to the sorting mechanism. Wikipedia has a good article with more detailed information on this machine,

Rollers inside of a Webendorfer printing press. Could the output of this device have been called "Web" pages?

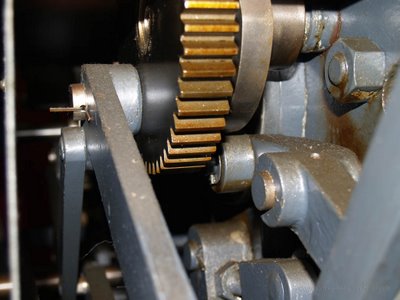

Close-up of some of the gearing on the Webendorfer.

Font Files.

A fully assembled page ready to press. Inset: the highlighted section of text flipped so it can be read.

1 comment:

Good blog you!

Post a Comment